Korzystając z tej strony, akceptujesz postanowienia Regulaminu i oświadczasz, że znasz naszą Politykę Prywatności.

Możesz określić warunki przechowywania lub dostępu do cookies w Twojej przeglądarce.

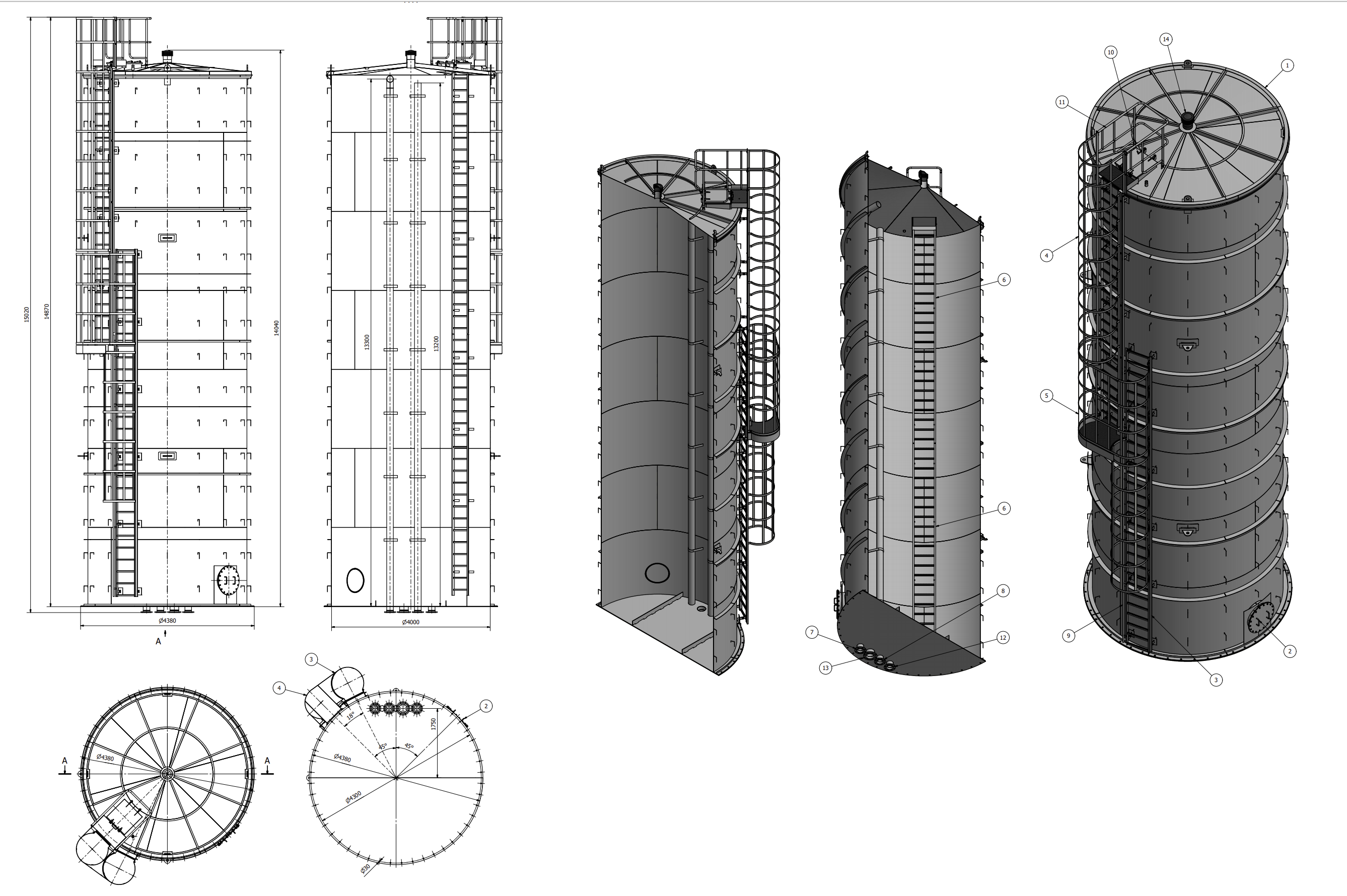

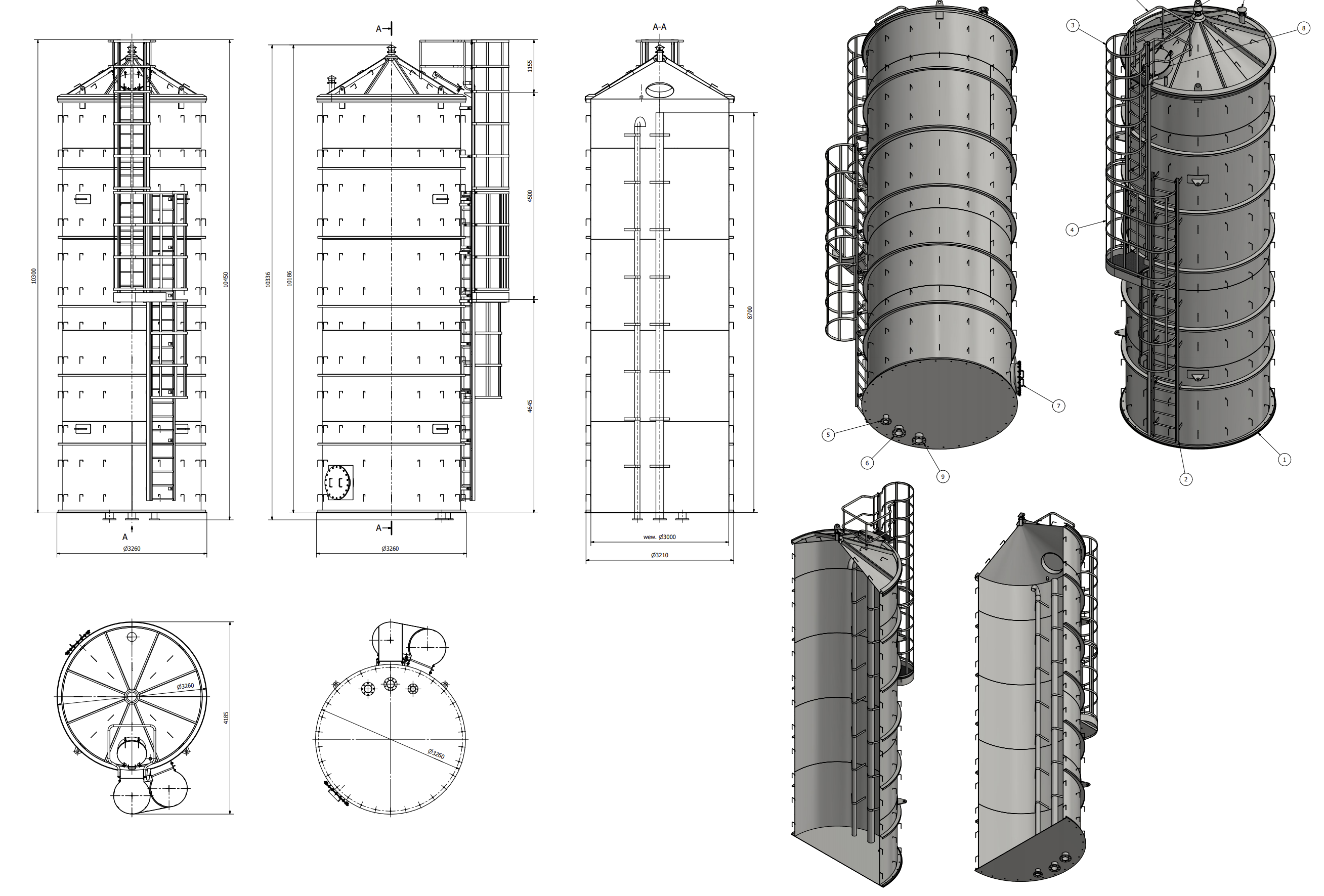

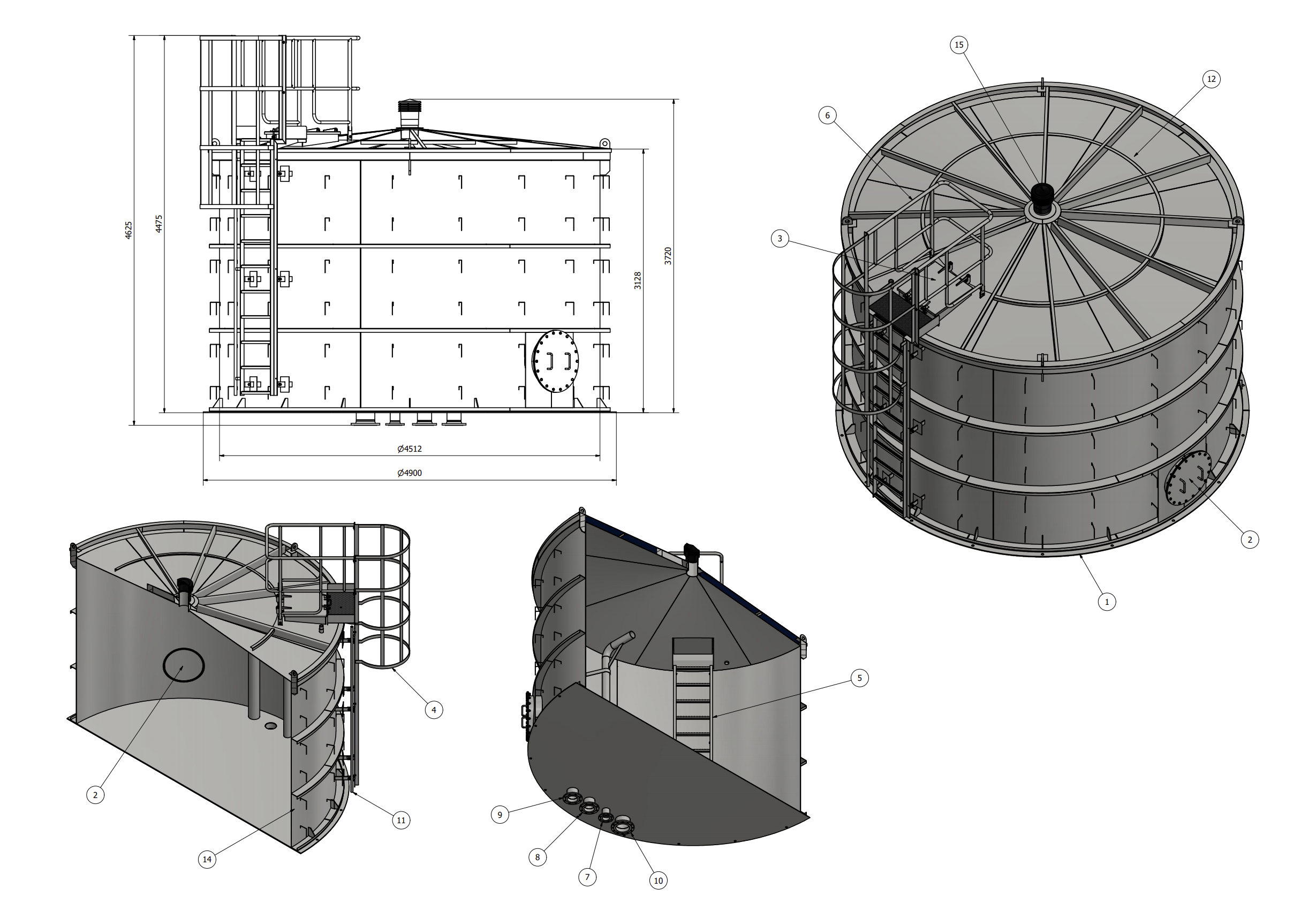

Potable water tank

Intended use

Vertical single-chamber retention tanks are used to store potable water to compensate for temporary water shortages, most frequently resulting from the inefficiency of wells at the intake in relation to water demands. Simultaneously, retention tanks constitute an additional source of firefighting water.

Water tank construction

Vertical retention tanks are made of low-carbon (approved) steel. Containers consist of a coat in the shape of a vertical cylinder with a flat bottom and a cone-shaped roof at the angle of 5%. The circumference of the bottom contains holes that are used to anchor the tank to the foundation slab.

A vent pipe is situated in the middle part of the roof, and a stub pipe for installing measuring probes that check water levels in the tank – near its top hatch.

The tank has two inspection hatches:

- on the roof, a rectangular hatch with an insulated cover,

- in the bottom part of the coat, a circular hatch with an insulated cover.

The tank has two ladders:

- external ladder, used to access the tank’s roof,

- internal ladder, used to access the inside of the tank.

The tank contains internal piping, used to fill and empty the tank. All connecting stub pipes end with a PN10 pressure flange.

The tank is a welded structure; the tightness of its welded connections is verified with penetration tests.

Heat insulation of the tank

The tank’s heat insulation is located on the outside of its steel coat and roof, and made of mineral wool with the density of 100 kg/m3. The tank’s inspection hatches are also insulated.

Mineral wool on the tank’s coat is further covered with galvanized trapezoidal steel sheets arranged vertically, painted with a chosen RAL colour; on the tank’s roof – with galvanized flat steel sheets, painted with a chosen RAL colour.

Anti-corrosion protection

All elements of the tank (excluding galvanizing elements) are shotblasted to the Sa 2½ standard. From the inside, the tank is coated with the BRANTHO-KORRUX paint (trade name) attested by the PZH (National Institute of Hygiene), thickness of the coating being 100 µm. All external elements of the tank are coated with epoxy primer, thickness of the coating being 60 µm; in addition, all non-insulated protruding elements are painted with polyurethane top coat in a chosen RAL colour, thickness of the coating being 80 µm. The outside of the bottom of the tank is coated with asphalt primer modified with SBS rubber, thickness of the coating: 100 µm.

External ladder and its safety railing have galvanized coating, as per PN-EN-ISO 1461 standard.